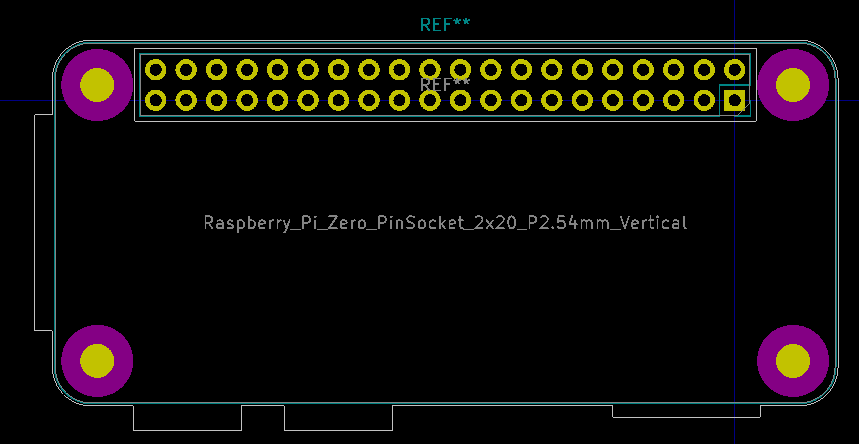

Add Raspberry Pi Zero footprint using Through-hole pin socket

To use a Raspberry Pi Zero ("W" model too) as a daughter board. Pin header would be soldered on the Raspberry Pi Zero and the main board uses a pin socket. No specific schematic symbol at the moment. A standard Pin socket can be used in the meantime.

Notes about dimensions:

- Official Mechanical drawing: https://www.raspberrypi.org/documentation/hardware/raspberrypi/mechanical/rpi_MECH_Zero_1p2.pdf

- Dimensions of the PCB are pretty well defined on the drawing, not a problem.

- Connectors:

- 1x 40-pin header: well defined in the drawing, not a problem.

- 2x micro USB, 1x mini HDMI: location around the outline is defined, but not their size nor how much they stick out which I have measured on a real unit.

- 1x camera FFC: not in the drawing so measured on a real unit.

- Please note that it's all mirrored left-right against the drawing since the components on the Raspberry Pi Zero would face down so that pin 1 matches pin 1.

Considerations taken:

- Origin at pin 1.

- Fab shows the real dimensions of the PCB but not the external connectors.

- Courtyard uses 0.25 mm clearance all around except around the connectors where uses 0.5 mm clearance.

- Silkscreen just outside of the module (half-width out) and not showing the shape of the connectors.

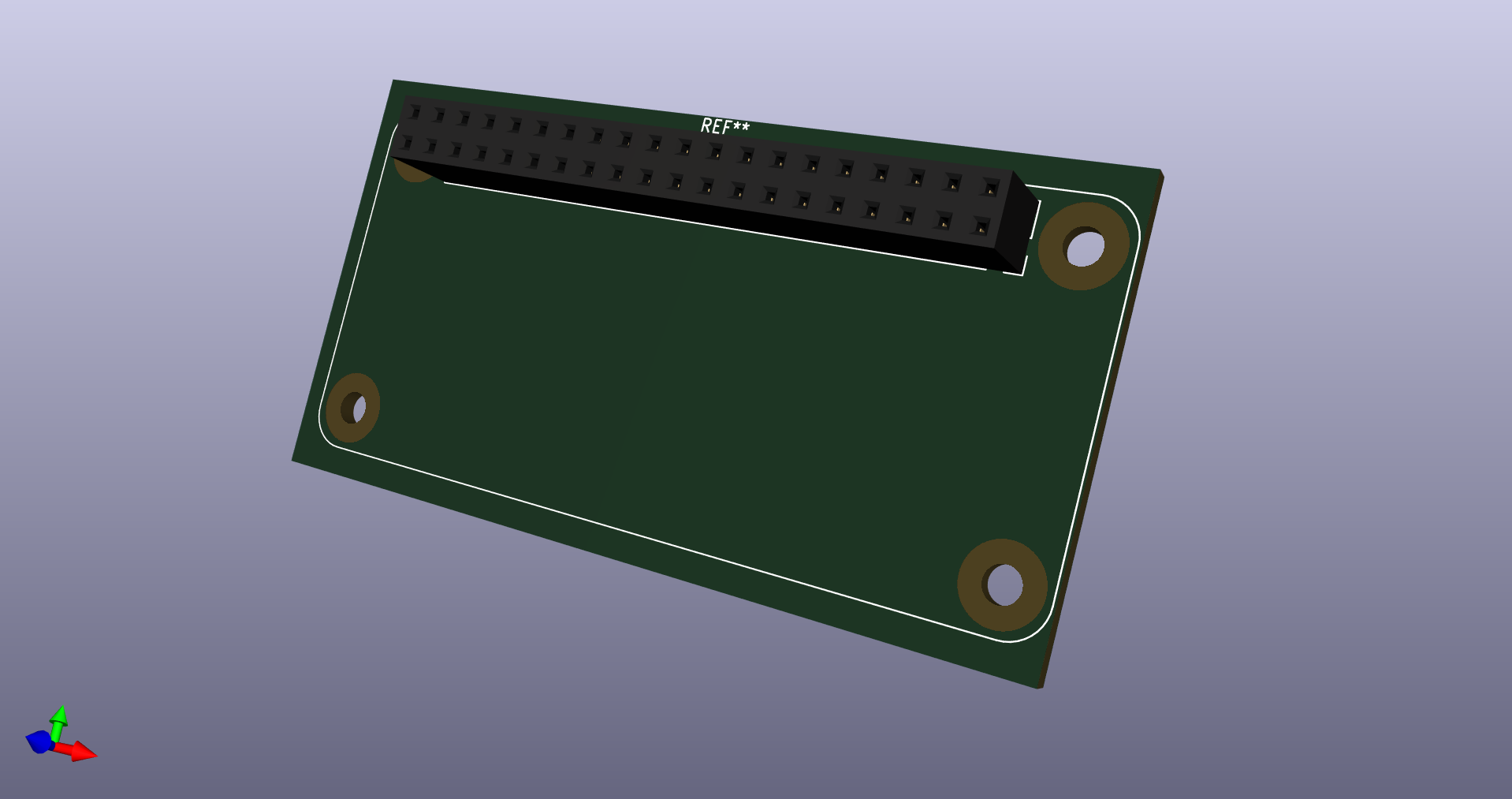

- Socket copied from PinSocket_2x20_P2.54mm_Vertical. It still contains all the layers from it (Fab, Silk, etc.) which I think that can be useful when designing a board (given the module will be raised up you can place components underneath).

- 3D model of the socket rotated 90 degrees. I know that KLC says no rotation or offsets different from zero but I think this makes sense in this case.

I've tried to stick to the KLC conventions but given it's not a "conventional" component it's not always straight forward.

Let me know if you want any changes.

Thanks.

Thanks for creating a pull request to contribute to the KiCad libraries! To speed up integration of your PR, please check the following items:

-

Provide a URL to a datasheet for the footprint(s) you are contributing -

An example screenshot image is very helpful -

If there are matching symbol or 3D model pull requests, provide link(s) as appropriate -

Check the output of the Travis automated check scripts - fix any errors as required